2023-08-30

Ton bag products have a wide range of applications, especially for powder and granular objects such as cement, grain, chemical raw materials, feed, starch, minerals, and even dangerous goods such as calcium carbide, which are packaged in bulk. Loading, unloading, transportation, and storage are all very convenient. Container bag products are currently in an upward stage of development, especially in the form of one ton or pallets (one pallet for one container bag, or four). The use of container bags in China is expanding, and the export of special purpose container bags such as calcium carbide and mineral products is also increasing. Therefore, the market demand potential for ton bag products is great, and the development prospects are very broad.

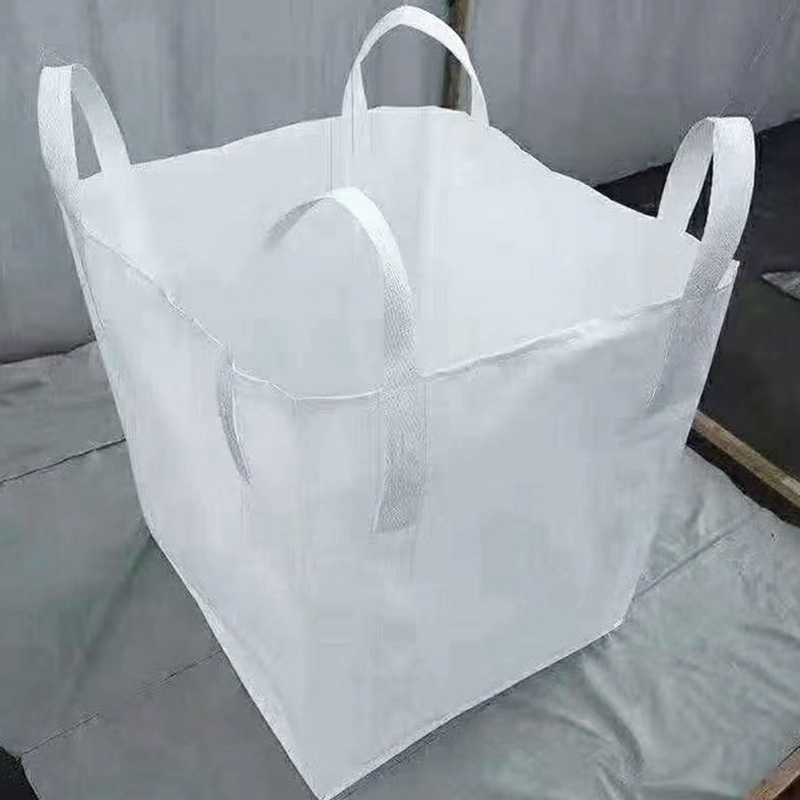

Ton bag (also known as container bag/space bag/flexible container/ton bag/ton bag/space bag/mother bag): It is a flexible transportation packaging container. It has the advantages of moisture-proof, dustproof, radiation resistant, sturdy and safe, and has sufficient strength in structure. Due to the convenience of loading, unloading, and transportation of container bags, the loading and unloading efficiency has significantly improved, and has developed rapidly in recent years. Container bags are generally woven from polyester fibers such as polypropylene and polyethylene. It is easy to transport bulk powder materials, with the characteristics of large volume, light weight, and easy loading and unloading, and is one of the common packaging materials. Its characteristics are simple structure, light weight, foldable, small space for return space, and low price.

Sichuan Rongda Technology Co., Ltd. is a large plastic products manufacturer, specializing in the research and development, production, sales and service of large plastic products. We mainly focus on container bags, tonnage bags, plastic trays, plastic sanitation bins, plastic crates, plastic baskets, plastic logistics boxes, plastic parts boxes, etc. We also undertake external processing of various plastic parts and auto parts, or in-mould processing. At present, the company has 60,000g and below injection moulding machines. Injection moulding: we specialise in the production of plastic trays, medical crates, sanitation bins, crates, baskets, wickets, plastic water tanks and various shaped customised products. Blow moulding: specialising in the production of plastic packaging drums, tonne drums, stacking barrels, PE water tanks, plastic storage tanks, dosing tanks, pickling barrels, aquatic square boxes, plastic fishing boats and other products. The products are of uniform thickness, resistant to pressure, collision, acid and alkali. At present, the company takes "high requirements in management, high quality in manufacturing" as the purpose, so that the company's products quickly open up the market in a short time. The company's products have also covered all provinces, cities, states, counties and other large, medium and small cities, and have been praised by the majority of customers.

He Shuyao

1527473323@qq.com

Dongying Builds China's Leading Public Testing and Certification Platform for Offshore Wind Power Industry

Hefei Spring Festival Gala Sub-Venue: Understanding the City’s “Union” Through Four Moments of Palms Meeting

Musician Dai Yutong Finds Inspiration in Ancient Xun County: 'True Art Stems from Deepest Roots'

MEXC Releases February Proof of Reserve Report, BTC Coverage Rises to 267%

Dreame Pens a ‘Love Letter to the World’ with Spring Festival Gala Partnership and Times Square Debut

Chinese humanoid robots gallop towards consumer market

©copyright 2009-2020 Diet Tips Daily